How to Improve Operational Efficiency: A Complete Guide for Modern Businesses

Understanding Modern Operational Efficiency

Operational efficiency is essential for business success, focusing on getting the most output from available resources like time, money and personnel. It’s not just about reducing costs – it’s about building smart processes that create real value. Recent research from IBM found that 77% of CEOs consider operational efficiency crucial for growing revenue.

Moving Beyond Old Methods

Many companies are shifting away from rigid approaches like strict budgets and aggressive quotas, which often hurt innovation and employee motivation. Instead, successful organizations create a culture of continuous improvement where staff actively spot inefficiencies and suggest better ways of working.

Success Stories in Action

Real companies have achieved major wins through smart operational changes. Take IT firms that struggled with resource bottlenecks – by using better planning tools and automating routine work, they cut project times in half while improving client results and reducing costs. These aren’t just isolated cases but proven frameworks other businesses can follow.

The path to better operations requires ongoing attention to the details that matter. Whether it’s redesigning workflows or adding tools to reduce manual tasks, companies that commit to efficiency while staying adaptable will see lasting benefits. The key is making changes that support both productivity and long-term stability.

Measuring What Matters: Performance Metrics That Drive Results

Basic KPIs alone don’t tell us enough about how well an organization runs. We need focused metrics that show exactly how effectively resources convert into results. Take manufacturing for example – unit production numbers matter, but resource usage per unit reveals the real efficiency story. This highlights why picking the right metrics is so important.

Choosing the Right Metrics for Your Business

The best performance metrics are actionable, measurable, and directly tied to business goals. Many companies make the mistake of tracking too many metrics, leading to confusion rather than clarity. Focus instead on a few key measures that clearly show opportunities to improve efficiency:

- Cycle Time: Tracking start-to-finish process duration helps identify bottlenecks and improvement areas

- Resource Utilization: Measures how well you use people, equipment and capital while avoiding burnout

- Defect Rate: Shows percentage of output needing rework, helping minimize waste

- Customer Satisfaction: Strong indicator of smooth internal operations and processes

By tracking these targeted metrics, companies can zero in on specific improvements. But choosing what to measure is just the start – you also need solid analysis.

Turning Data Into Actionable Insights

Getting the data is step one. The real value comes from the operational efficiency ratio – operating expenses plus cost of goods sold divided by net sales. When this ratio drops, efficiency improves. Visual dashboards displaying key metrics make it easier to spot issues and track progress on improvement projects.

Building a Culture of Continuous Improvement

Long-term efficiency requires ongoing attention. Setting clear benchmarks and regularly reviewing performance creates accountability throughout the organization. When every team member understands their role in optimizing processes and feels empowered to suggest improvements, you build momentum for sustained gains in efficiency and competitiveness.

Using Technology Effectively for Better Operations

Making operations more efficient requires choosing the right technology solutions deliberately. This means carefully selecting tools that address specific needs and contribute meaningfully to business goals, rather than adopting every new technology that comes along. By taking a focused approach, companies can get better returns on their tech investments and avoid implementing technology just for its own sake. For instance, a business struggling with disconnected data might prioritize a central data platform over the newest automation software.

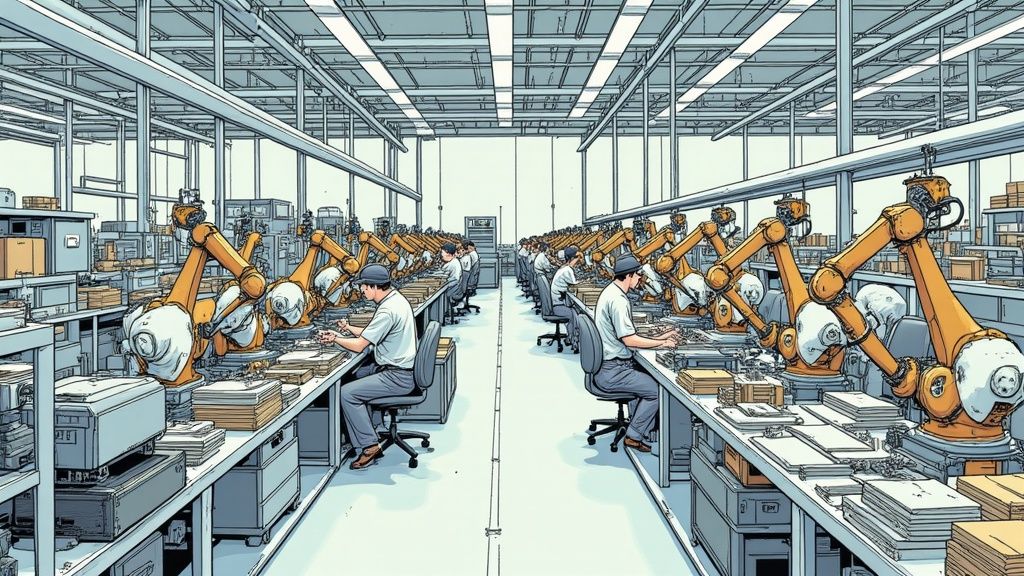

Using AI and Automation Effectively

Artificial intellignce (AI) and automation tools are practical solutions for improving operations today. These technologies help reduce manual work, minimize errors, and allow employees to focus on higher-value tasks. Take AI chatbots in customer service – they handle basic questions so human agents can spend time on complex issues and personalized support. Similarly, workplace management systems and resource planning software powered by AI and IoT help automate data entry and other manual processes, reducing mistakes and freeing up staff time.

Making Smarter Decisions with Data Analytics

Data analytics is key for finding ways to improve operations. By examining operational data closely, companies can spot bottlenecks and inefficiencies to make better decisions. For example, analyzing website data reveals opportunities to improve the user experience and increase sales. This shows how data helps understand not just what’s happening but why, so companies can make targeted improvements.

Combining Technology and Human Skills

While technology is crucial, it works best when paired with human expertise. This means training employees to use new tools effectively and fostering an environment where staff can suggest improvements and identify optimization opportunities. This combination of technology and human insight creates lasting operational advantages. For example, Shiny, which connects startups with experienced executives, demonstrates how technology can support human talent – making hiring more efficient while maintaining the human element. This balanced approach shows how technology and people can work together to improve operations.

Mastering Process Optimization and Workflow Design

Better operational performance starts with smarter workflows and processes. Like any well-maintained system, efficient workflows drive success by removing obstacles, minimizing waste, and improving quality while boosting output speed.

Identifying and Eliminating Bottlenecks

Picture a four-lane highway with one lane closed – traffic slows significantly even though most lanes remain open. Business operations face similar bottlenecks that restrict work progress. Common examples include slow approvals or not having enough skilled staff for key tasks. The first step is using process mapping to find these slowdowns. Map out each workflow step, noting dependencies and potential delay points.

Streamlining Workflows for Maximum Efficiency

After finding bottlenecks, organizations can take specific steps to remove them. Using software to automate routine data entry or complex processes frees up employees to focus on higher-value work. Cross-training team members helps address skill gaps and builds adaptable teams that can handle shifting workloads.

Implementing Effective Standard Operating Procedures

Standard Operating Procedures (SOPs) create consistency and quality across teams. These procedures provide clear task guidance while minimizing errors and variations. However, SOPs should stay flexible – regular reviews and updates ensure they match current needs and best practices while supporting operational goals.

Building Adaptable Workflows

Business demands shift constantly, requiring workflows that can evolve smoothly. Flexibility in workflow design is key for maintaining excellence as conditions change. Build processes that scale up or down easily and include feedback loops to spot areas needing improvement. Just as Shiny helps startups flexibly adjust their executive teams, adaptable workflows let businesses respond nimbly to market shifts. Smart workflow design and continuous refinement help companies achieve operational efficiency that fuels both growth and profits.

Creating a High-Performance Operations Culture

How your company’s work environment affects daily operations has major impact on results. Just like a smoothly running machine needs well-synchronized parts, a workplace where everyone collaborates efficiently leads to better outcomes. The goal is creating an environment where productivity becomes natural throughout the organization.

Engaging Teams in Continuous Improvement

When building a high-performance operations culture, start by involving your whole team. Staff members who feel valued and supported are more likely to spot ways to make processes better. Regular team brainstorming sessions and open feedback channels help capture useful ideas. Giving recognition and rewards to employees who enhance efficiency encourages more people to contribute constructively.

Developing Effective Training Programs

Strong training programs equip staff with essential skills for peak performance. Different roles need different training approaches – sales teams may focus on CRM mastery while production staff learn new manufacturing methods. By matching training to specific needs, programs deliver more value.

Fostering Innovation at All Levels

Efficiency and creative thinking work together. When employees feel safe to experiment and learn from setbacks, they find smart ways to improve processes. Look at companies like Google, where supporting innovation translates into streamlined operations. This open mindset leads to practical workflow upgrades.

Building Sustainable Momentum for Change

Maintaining progress requires ongoing attention. Regular progress reviews, celebrating wins, and reinforcing efficiency principles keep improvements on track. Just as Shiny connects startups with skilled executives, consistent reinforcement makes efficiency central to company culture. This steady focus creates lasting operational gains.

Measuring and Reinforcing Cultural Change

Tracking how cultural shifts affect operations provides key insights. Important metrics include:

- Employee engagement levels

- Number of process improvement ideas

- Error rates and quality measures

This data shows what’s working and where adjustments are needed. For example, if engagement stays low after new programs launch, companies can refine their approach. Using metrics ensures the culture continues strengthening operational excellence.

Implementing Your Operational Excellence Strategy

Creating real improvements in operations requires careful planning and systematic execution. A successful strategy needs to work seamlessly with daily activities while being robust enough to handle real-world challenges. Let’s explore how to put your operational excellence plans into action.

Building Your Implementation Plan

Start with a clear roadmap that outlines your goals, methods, timeline and required resources. This serves as your guide through the implementation process and helps keep all efforts aligned.

- Define Clear Goals: Identify specific targets for operational efficiency – whether that’s reducing waste, improving speed, or enhancing quality

- Create Checkpoints: Break the implementation into smaller milestones to track progress and recognize achievements

- Deploy Resources Effectively: Ensure you have the right mix of people, tools and technology. Shiny can connect you with experienced executives who can guide this transition on a part-time basis.

Leading Change Successfully

Making operational changes often meets resistance. Success requires clear communication and getting everyone involved in the process.

- Keep Teams Informed: Share updates about policy changes and explain their benefits

- Build Support: Include key stakeholders early to gain their backing and prevent potential issues

- Give Staff a Voice: Create channels for employees to provide feedback and suggestions on changes

Managing Risks and Tracking Results

Have plans ready to address potential problems before they arise. Put systems in place to measure progress and ensure you’re moving toward your goals.

- Monitor Risks: Regularly check processes to spot potential issues that could slow progress

- Track Key Metrics: Measure results that connect directly to your operational goals, like cost reductions and efficiency gains

Getting operational excellence right takes more than just planning – it requires building adaptable strategies that promote ongoing improvement. With strategic focus, supportive culture, and tools like Shiny to bring in expert help when needed, you can create lasting operational transformations.