Mastering Manufacturing Operations Management: A Guide to Efficiency and Growth

Think of Manufacturing Operations Management (or MOM) as the conductor of your factory's orchestra. It’s the hands-on system ensuring every part of your operation—from the supply chain and production to quality control and shipping—works in perfect harmony. The goal? To turn raw materials into finished goods efficiently and profitably.

For a growing business, mastering MOM is the difference between simply making products and building a scalable, resilient manufacturing engine. But you don't have to figure it out alone.

What Is Manufacturing Operations Management?

Picture a high-performance race car team during a pit stop. Every person has a specific job, every tool is exactly where it needs to be, and every split-second counts. Manufacturing operations management is the strategic framework that coordinates this same level of precision on a factory floor.

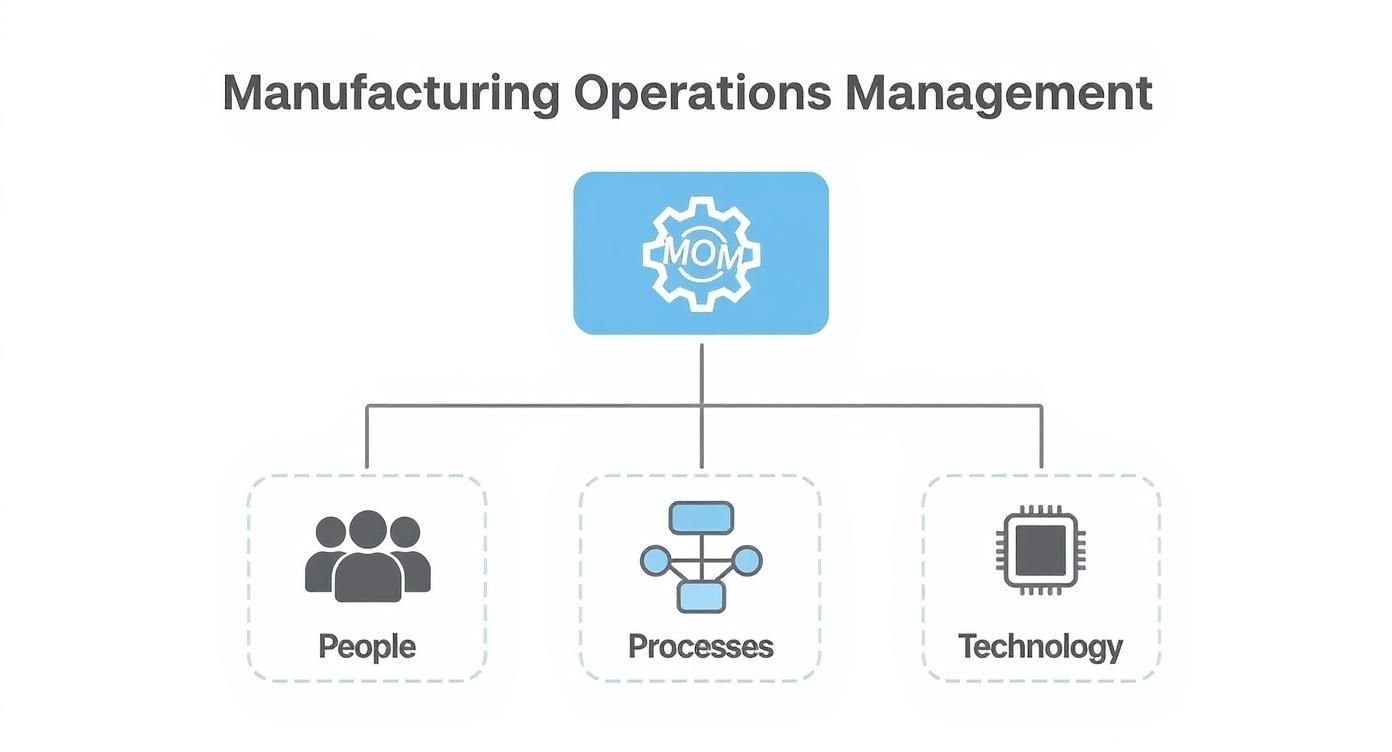

This isn't just about a piece of software or a single department's responsibility. It's a business philosophy that weaves together your people, processes, and technology to optimize the entire production lifecycle. It addresses the core pain points that keep owners up at night: production delays, quality issues, and shrinking margins.

The Core Purpose of MOM

At its heart, MOM creates a production environment that is predictable, efficient, and consistently high-quality by focusing on key areas:

- Real-Time Visibility: Giving you a crystal-clear, up-to-the-minute view of everything happening on the shop floor—machine status, employee performance, and material flow.

- Process Enforcement: Making sure every product is built to the correct specifications and quality standards, every single time.

- Resource Optimization: Squeezing the most value out of your machinery, materials, and labor to slash waste and maximize output.

- Data-Driven Decisions: Collecting and analyzing production data to spot bottlenecks, improve processes, and make informed choices instead of just guessing.

MOM is the bridge between the boardroom's grand plans and the factory floor's daily grind. It translates big-picture goals like "increase profit margins" into real, actionable tasks like "reduce cycle time by 5%."

This disciplined approach is becoming more critical than ever. The global market for manufacturing operations management solutions has ballooned, valued at around $15 billion in 2025. Projections show it climbing at a compound annual growth rate of 8% through 2033. You can discover more insights about this growing market from Archive Market Research.

For small and mid-sized businesses, getting a handle on MOM principles is what separates the struggling operators from the true market leaders. Without it, you’re just assembling products; with it, you’re building a profitable manufacturing engine.

Understanding the Pillars of Modern Manufacturing

A strong manufacturing operation isn’t built by accident. It’s the result of several core disciplines working in perfect sync, much like the legs of a sturdy table. To build a resilient and profitable business, you have to master these pillars of manufacturing operations management (MOM).

It all comes down to the seamless integration of your people, processes, and technology.

As the infographic shows, you only hit operational excellence when skilled people execute well-defined processes using the right technology. Let one of these legs get wobbly, and the whole system starts to falter.

Now, let's break down the four key process pillars that bring this structure to life.

Production Planning and Scheduling

This is the strategic game plan for your entire operation. It answers the big questions: What are we making? How much do we need? And when does it need to be done? It involves forecasting demand, lining up resources, and creating a master schedule that keeps everything on track.

Think of it as the air traffic control for your factory. Without it, you have chaos—machines sitting idle, materials arriving too early or too late, and missed deadlines.

Quality Management

Quality management is your non-negotiable commitment to excellence. It’s a systematic approach to ensuring every product meets—or exceeds—customer expectations. This isn't just about inspecting finished goods; it’s about baking quality into every step.

This includes:

- Supplier Qualification: Vetting raw material suppliers to guarantee quality from the start.

- In-Process Checks: Running inspections at critical points on the line to catch defects early.

- Root Cause Analysis: When a quality issue pops up, you dig deep to find out why it happened and make sure it never happens again.

Effective quality management shifts the focus from finding defects to preventing them. It’s the difference between having a fire department and having a fire prevention plan—one is reactive, the other is strategic.

Inventory and Supply Chain Control

Inventory control is the delicate art of balancing supply and demand. Too much inventory ties up cash and costs money to store. Too little, and you risk stockouts and angry customers. This pillar is all about optimizing the flow of materials into, through, and out of your facility.

For example, a craft brewery needs precise inventory control to manage seasonal ingredients. They must have enough specialty hops for a limited-run IPA without overstocking on perishable items. Tight supply chain coordination is critical.

Maintenance Management

Nothing kills productivity and profits faster than unplanned downtime. Maintenance management is the science of keeping your equipment in peak condition. A single unexpected breakdown can bring a production line to a grinding halt.

Modern maintenance is proactive:

- Preventive Maintenance: Regularly scheduled service—like changing a machine's oil—to prevent failures before they happen.

- Predictive Maintenance: Using sensors and data to monitor equipment health in real-time, predicting when a failure is likely to occur so you can schedule repairs during planned downtime.

Key MOM Pillars and Their Business Impact

This table breaks down how each of these core functions directly contributes to the bottom line.

| MOM Pillar | Core Function | Primary Business Impact |

|---|---|---|

| Production Planning | Forecasting demand, resource allocation, and creating master schedules. | Improves on-time delivery, reduces lead times, and maximizes resource utilization. |

| Quality Management | Setting quality standards, in-process checks, and root cause analysis. | Reduces defects and rework, increases customer satisfaction, and ensures compliance. |

| Inventory Control | Managing raw materials, WIP, and finished goods to balance supply and demand. | Frees up working capital, reduces storage costs, and prevents stockouts. |

| Maintenance Management | Proactive servicing of machinery and equipment to prevent failures. | Minimizes unplanned downtime, extends asset life, and improves production output. |

By mastering these four pillars, you create a robust framework for success. If you recognize gaps in any of these areas, exploring fractional leadership can provide the expert guidance needed to strengthen your operational foundation without the commitment of a full-time hire.

The KPIs That Actually Drive Improvement

In manufacturing, it’s easy to drown in data. The trick is to look past "vanity metrics" and zero in on the Key Performance Indicators (KPIs) that truly reveal the health of your factory floor.

You can't improve what you don't measure. The right KPIs act as your operation's vital signs, telling a direct story about where you’re succeeding and, more importantly, where you’re bleeding money.

Measuring What Matters Most

Focusing on a handful of powerful KPIs is far more effective than tracking dozens of less important ones. For most manufacturers, success boils down to a few core metrics that cover quality, speed, and reliability.

-

Overall Equipment Effectiveness (OEE): The gold standard for measuring productivity. It rolls three critical factors—Availability (uptime), Performance (speed), and Quality (good parts)—into a single score. A world-class OEE is around 85%.

-

Cycle Time: How long it takes to produce one unit from start to finish. A shorter cycle time means higher throughput and a greater ability to meet customer demand.

-

First Pass Yield (FPY): A potent quality metric measuring the percentage of products made correctly the first time, without any rework. A low FPY is a major red flag pointing to costly problems.

-

On-Time Delivery (OTD): This customer-facing KPI tracks the percentage of orders delivered by the promised date. A high OTD rate is essential for keeping customers happy and loyal.

A sudden drop in First Pass Yield isn't just a number on a chart; it's a symptom of a deeper problem. It could signal a bad batch of raw materials, a machine falling out of calibration, or a need for better operator training—all issues that silently erode your profit margins.

Bringing Your KPIs to Life

Collecting data is only half the battle. To make these numbers useful, you have to present them in a way that gives you clear, actionable insights. This is where a well-designed dashboard becomes an indispensable tool.

Visualizing your KPIs helps everyone, from the CEO to the shop floor supervisor, understand performance in real-time. For instance, you could see OEE trending down on a specific machine, prompting a maintenance check before a major failure. You can explore different executive dashboard examples to see how top-performing companies track their success.

Using KPIs to Drive Decisions

Once you're consistently tracking the right metrics, you can start using them to drive real change.

Imagine your On-Time Delivery rate dips from 98% to 92%. By digging into the data, you might discover the root cause isn't production speed but a bottleneck in the final packaging stage. Armed with that insight, you can reallocate resources or redesign the workflow in that specific area, addressing the actual problem.

This data-driven approach takes guesswork out of your manufacturing operations management. It builds a culture of continuous improvement where every decision is backed by hard evidence.

How Technology Is Reshaping the Factory Floor

Digital transformation isn't just a buzzword for massive corporations anymore. Today, powerful and accessible technology is fundamentally changing how small and mid-sized manufacturers operate, compete, and win.

This shift is turning traditional factories into smart, interconnected ecosystems where data provides unprecedented insight.

At the heart of this evolution is modern Manufacturing Operations Management (MOM) software. Think of it as the digital command center for your entire production process, connecting siloed systems, machinery, and people into a single, real-time view. This isn't just about swapping clipboards for tablets; it's about gaining the control needed to make faster, smarter decisions.

Key Technologies Driving the Change

A handful of core technologies are powering this new era of manufacturing. When brought together thoughtfully, they create a more efficient and profitable operation.

-

The Internet of Things (IoT): An IoT sensor on a machine acts like its personal fitness tracker, constantly monitoring vitals like temperature and vibration. This allows for predictive maintenance—fixing a problem before it causes a costly failure.

-

Cloud Computing: The cloud has leveled the playing field for SMBs. Cloud-based MOM solutions offer powerful tools on a flexible subscription basis, making advanced tech more affordable and scalable than ever.

-

Artificial Intelligence (AI) and Machine Learning (ML): If IoT sensors collect the data, AI is the brain that makes sense of it. It can spot subtle patterns to optimize schedules, predict quality issues, and improve your yield.

Technology is the nervous system of the modern factory. IoT sensors are the nerve endings, the cloud is the spinal cord transmitting signals, and the MOM software is the brain making sense of it all to coordinate intelligent action.

This rapid adoption is fueling serious market growth. The global manufacturing operations management software market is projected to rocket from $19.63 billion in 2025 to a massive $44.41 billion by 2030. You can explore more projections about the MOM software market to get a sense of this shift.

Making Technology Work for Your SMB

The idea of implementing this tech can feel daunting, but it doesn’t have to be a giant project. The secret is to start small. Focus on the areas that will deliver the biggest impact for your specific business.

A successful tech implementation is less about the tools and more about having a clear plan. For many SMBs, the best first step is building a solid digital transformation roadmap. It gives you a structured path to ensure your investments solve real-world problems.

Navigating this change often requires an expert guide, which is where fractional operations leadership can provide immense value, making sure your tech investments translate directly into business growth.

Navigating Common Implementation Challenges

Rolling out a major change in your manufacturing operations management is like a home renovation. You can have the perfect blueprint, but you’re still going to hit some snags. The key isn't dodging every problem; it's knowing the common hurdles so you can build a smarter plan.

Too many businesses jump into an operational overhaul with enthusiasm, only to watch their efforts stall because of predictable challenges. Honest foresight sets your project up for a much smoother ride.

Overcoming Resistance to Change

One of the biggest obstacles isn't technical; it's human. Your team, especially veterans, are often skeptical of new systems. They might see it as a threat, a disruption, or just another "flavor of the month" initiative.

Your best tools to counter this are communication and involvement.

- Involve Your Team Early: Before you finalize anything, bring shop floor supervisors and key operators into the planning process. Show them exactly how the new system will solve their biggest daily headaches.

- Create Champions: Empower influential team members who are open to the change to be advocates. A recommendation from a trusted peer is far more powerful than a memo from the boss.

- Show, Don't Just Tell: Set up a small pilot project on a single line. When the rest of the crew sees real improvements—less rework, simpler scheduling—skepticism will start to melt away.

Breaking Down Data and Departmental Silos

Another common trap is the silo effect. This happens when your quality, production, and maintenance departments all run on separate spreadsheets. Without a single source of truth, you get conflicting data, crossed wires, and a lot of finger-pointing.

A siloed operation is like trying to navigate a ship with multiple captains, each looking at a different map. Everyone might be working hard, but they aren't working together, and the ship isn't moving in the right direction.

Effective manufacturing operations management is built on integrated data. The goal is a unified view where information flows seamlessly between departments, so everyone makes decisions based on the same accurate, real-time information.

This push for integration is a major reason the market is growing so fast. In Europe, for example, MOM software is projected to see a CAGR of 19.1%, driven by initiatives that demand connected systems. You can learn more about these manufacturing growth trends.

Getting past these challenges demands strong leadership. If your team doesn't have the bandwidth or specific expertise, bringing in fractional leadership can provide the seasoned guidance you need to ensure your transformation delivers on its promise.

Accelerate Growth with Fractional Operations Leadership

Many small and mid-sized manufacturers hit a wall. Growth stalls, inefficiencies creep in, and the operational complexity becomes too much for the founding team to handle.

This creates a tough paradox. You know you need executive-level operations expertise to scale, but the $200,000+ annual salary for a full-time Chief Operating Officer (COO) isn't in the budget.

This is exactly where fractional leadership comes in as a powerful, flexible solution. It’s a model built for growing businesses that need top-tier talent without the full-time price tag.

What Is a Fractional Operations Leader?

Think of a fractional operations leader as your on-demand, executive-level expert in manufacturing operations management. This is a seasoned pro—often a former COO or VP of Operations—who joins your team for a set number of hours each week or month.

They deliver the same high-level strategic guidance, team mentorship, and project execution you'd get from a full-time hire, but at a fraction of the cost. A fractional leader becomes a true part of your leadership team, rolling up their sleeves to get things done on your factory floor.

How a Fractional Leader Drives Real Results

A great fractional executive can step in and make an immediate impact by zeroing in on the high-priority areas that deliver tangible returns.

- Bridging the Expertise Gap: They bring specialized know-how in areas like Lean manufacturing, supply chain optimization, or quality control systems that your current team may not have.

- Overseeing Complex Projects: Managing a major tech implementation, like a new MOM or ERP system, is a huge undertaking. A fractional leader can own that project, keeping it on track and on budget while your team focuses on daily production.

- Mentoring Your Internal Team: They coach and develop your existing managers, building their skills so they can take on more responsibility down the line. It's an investment that creates lasting internal capability.

A fractional COO acts as an operational accelerator. They bring the strategic roadmap and the hands-on experience to bypass common scaling mistakes, helping your company achieve in months what might otherwise take years of costly trial and error.

This model is a game-changer for businesses at a critical inflection point. Whether you’re gearing up to launch a new product line or struggling to improve profit margins, an experienced guide can make all the difference. For those curious about this role, our complete guide to hiring a fractional COO offers a deeper dive into the process and benefits.

If needing senior expertise without the full-time budget sounds familiar, it may be time to explore a more agile leadership model. Connecting with the right fractional executive can unlock new levels of efficiency and profitability.

Frequently Asked Questions

Jumping into manufacturing operations management brings up a ton of questions, especially for a growing business. Let's tackle some of the most common ones.

Where Should an SMB Start with Improving MOM?

Before you think about new software, start with a simple, honest audit. Grab a whiteboard and physically map out your entire workflow—from the second a customer order lands to the moment it ships out the door.

This simple exercise is incredibly revealing. It forces you to see exactly where your biggest bottlenecks are, where waste is piling up, or why quality issues keep cropping up. Without this fundamental understanding, any money you spend on tech is just a shot in the dark. You need to aim your resources at the real problems to get a real return.

How Is MOM Different from an ERP System?

It's a classic mix-up, but the distinction is clear when you think about it. Imagine your company is building a house.

Your Enterprise Resource Planning (ERP) system is the architect with the master blueprint. It’s handling the big-picture stuff: the budget (finance), the client's order (sales), and ordering the lumber (high-level resource planning). The ERP decides what house to build.

Manufacturing Operations Management (MOM), on the other hand, is the general contractor on the job site. It takes the blueprint and makes it happen in the real world, minute by minute. MOM is managing the crew, doing quality checks on the foundation, and solving problems on the ground. It’s all about the how.

Is a Fractional Operations Leader Only for Turnarounds?

Not at all. While fractional leaders are rockstars in a crisis, their biggest impact often comes from steering proactive, intentional growth.

A fractional executive is a strategic investment in capitalizing on opportunity, not just a reactive fix for a problem. They help you scale the right way the first time and avoid expensive missteps.

Growing SMBs bring in fractional COOs to hit forward-looking targets like:

- Scaling up production capacity before you're overwhelmed by demand.

- Nailing the launch of a new product line—on time and on budget.

- Smoothly integrating the operations of a company you just acquired.

- Mentoring your existing team to build your next generation of in-house leaders.

It's about getting top-tier expertise exactly when you need it to build a more resilient, profitable business for the long haul.

Ready to stop guessing and start scaling? Shiny connects you with a marketplace of vetted, on-demand executives who can drive immediate impact in your manufacturing operations. Schedule a consultation to find your perfect fractional leader.